-

Company

-

Company profile

Company profile

- Leading manufacturer of spindle systems

- Innovation when it comes to high-quality, high-frequency spindles

- Tradition of customer focus

-

Made in Germany

Made in Germany

- Leading manufacturer of spindle systems

- Innovation when it comes to high-quality, high-frequency spindles

- Tradition of customer focus

-

Quality control

Quality control

- Top quality guarantees top satisfaction

- Stability, reliability, and the best material

- Continuous investment in quality control

-

Research & development

Research & development

- Work on spindle systems of the future

- Continuous optimization of spindles already used

- Special spindle systems for individual tasks

-

Motor construction

Motor construction

- Development and production of our own motor elements

- Performance of the motors is inspected in house.

- Optimum coordination of the frequency converters

-

Areas of application

Areas of application

- Diverse potential applications

- The right spindle for every purpose

- Reliability and precision in every field

-

Company profile

-

Products

-

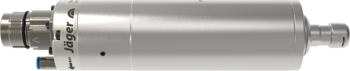

Z-Line

Z-Line

- Highest precision, stability, and running smoothness

- Rated power up to 10 kW

- Rated rotation speed up to 100.000 U/min

-

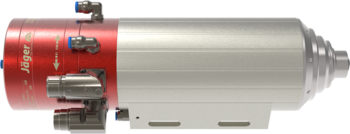

F-Line

F-Line

- Customized flange types

- Rated power up to 67 kW

- Rated rotation speed up to 50.000 rpm

-

ARS-Line

ARS-Line

- Dressing grinding wheels

- Higher precision

- Accurate grinding

- Cut detection

-

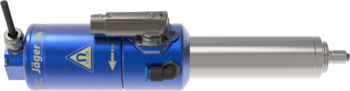

Block-Line

Block-Line

- Individually manufactured block housing

- Various clamping systems

- Rated rotation speed up to 60.000 rpm

-

Chopper

Chopper

- Various clamping systems in one basic body

- Rated power up to 6,5 kW

- Rated rotation speed up to 40.000 rpm

-

DentaDrive

DentaDrive

- Modular unit assembly system

- Individually configurable

- Rated power up to 0,31 kW

- Rated rotation speed up to 100.000 rpm

-

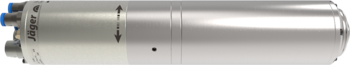

Power-Line

Power-Line

- More output with the same housing diameter

- Rated power up to 3,7 kW

- Rated rotation speed up to 80.000 rpm

-

Z-Line

-

Motors

-

Motor construction

Motor construction for:

- Spindle motors

- Electric motors

- Custom-made products

-

Areas of application

Areas of application

- Motors for HF spindles

- Motors for pumps and automation

- E-mobility

- Motors for turbo compressors and generators

-

Motor inquiry

Configure your individual motor

- AC motors

- DC motors

- Special motors

-

Nakanishi Jaeger PTT

Nakanishi Jaeger PTT

Powertrain technology

Our standard motors- Asynchronous technology

AC motors - Synchrotechnology

DC motors

- Asynchronous technology

-

Motor development

Individual motors, specially for your application

- Solutions for the entire process chain

- Takeover of the development service

- Contract manufacturing

-

Our standard motors

Our standard motors

- AC motor

- DC motor

-

Motor construction

- Service

- Currently

- Contact Us